Business

From John Deere to TecnoCientifica: Plowing New Paths in Precision Agriculture

For the last 30+ years, a quiet agricultural revolution has been taking place that largely evaded mass attention until the 2024 solar storms made headlines for some unexpected reasons. However, while GPS-guided tractors working to inch-perfect precision may have been what captured the headlines, they’re just the very tip of the precision agriculture iceberg. Here, we take a closer look.

When the most powerful solar storms in 25 years hit in May of this year, it was more than just the atmospheric light shows that captured our attention. From the New York Times to smaller independent news outlets, one of the biggest stories had little to do with astronomy, and everything to do with agriculture. Or, more precisely, precision agriculture.

Unfortunately for many farmers, the 2024 solar storm hit right at the peak of planting season, degrading the accuracy of the GPS systems used on many farms for guiding tractors while planting fields. And while most of us would have struggled to notice any impact at all, that’s only because we don’t need navigational accuracy down to the nearest inch. For farmers reliant on GPS systems, however, inch-perfect accuracy can make the difference between a bumper season and a double-digit percentage loss, such are the demands of today’s precision agriculture techniques.

For many of us, this might have come as a surprise, perhaps making this year our first real awakening to just how far agricultural technology has advanced. However, despite its traditional, rustic connotations, what many of us may not have realized is that agriculture is now approaching its fourth decade of increasing reliance on ever more sophisticated systems; systems that have come out of a movement broadly known as precision agriculture.

The Rise of Precision Agriculture

When the last big solar storm hit in 1989, the Green Revolution that began in the 1940s had largely passed its peak. Further improvements in crop varieties, chemical inputs, and irrigation systems had more or less reached the point of diminishing returns, creating a void as scientists scrambled to find the next big agricultural breakthroughs.

Almost simultaneously, this saw the emergence of two new avenues for agricultural optimization. The first, which has since garnered much public attention is, of course, the field of Genetically Modified Organisms (GMO), with the first GMO plant being created in 1983. The second, which had largely lived in GMO’s shadows until the 2024 solar storm created agricultural headlines, was the idea of using high-tech innovations in agricultural practices. This led to the emergence of precision agriculture.

By the 1990s, precision agriculture had moved from theory to practice with the emergence of variable rate applicators and yield maps. When combined with GPS technology, these innovations allowed farmers to correlate yield data with spraying and planting data to optimize crop planting and management across increasingly smaller subsections of any given field.

Of course, as technology has advanced, so too have the benefits of precision agriculture. And these benefits haven’t been confined to the inch-perfect GPS systems like John Deere’s RTK which we saw degraded in the 2024 solar storms. Today, all manner of geo-referenced real-time and historical data is combined to continuously optimize crops not only for crude measurements like gross yields but also for crop quality.

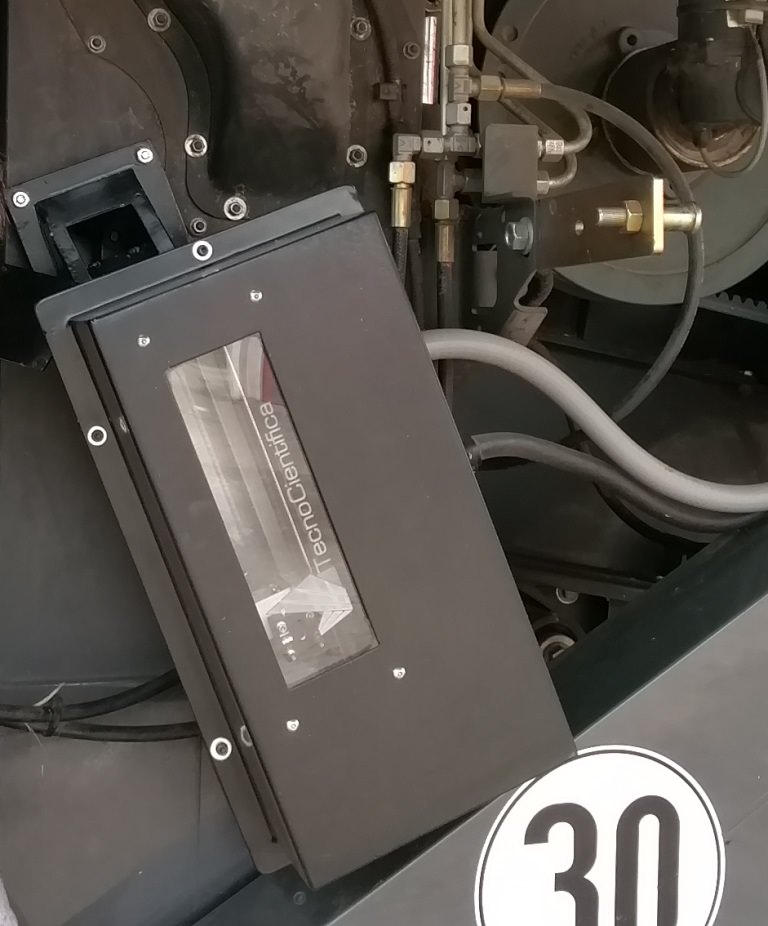

At the forefront of these innovations are systems like TecnoCientifica’s GRAIN-Q. This system uses real-time Near-Infrared Spectroscopy (NIRS) to analyze properties like the moisture, protein, fat, and starch content of crops at the very moment crops are harvested. Immediately, what this enables is for farmers to go beyond simple measurements like the gross yields used in early precision agriculture, and to really hone in on the precise quality of crops across sections of a field. However, the benefits go far beyond the field.

Precision Agriculture Spills Over Beyond the Field

Taken at face value, the benefits of TecnoCientifica’s GRAIN-Q system aren’t particularly revolutionary. After all, techniques for measuring properties like fat and protein content have been around since the late 1800s. In theory, all a farmer had to do was package up some samples, send them to a lab, and wait patiently for the results to come back. Of course, this is both cumbersome and time-consuming.

This is where systems like the GRAIN-Q change the game. Integrated directly into harvesting equipment, they provide all of this data in real-time, right there at the point of harvest. Not only does this allow the collection of data across any given subdivisions of a field at an incredibly high resolution, but it also unlocks multiple benefits that simply weren’t possible before, not the least of which is the ability for the farmer to make real-time decisions.

However, this is just the beginning of what is possible with real-time NIR spectroscopy. One of the more notable benefits — something that early precision agriculture researchers could only have dreamed of — is the ability to actively sort grains according to quality as they are harvested. And the benefits that come with this flow well beyond the field right up the entire supply chain.

Immediately for the farmer, actively sorting grains delivers two distinct advantages. The first of which is the ability to sort higher quality grains from lower quality grains. This allows them to fetch premium prices on what is sometimes a significant percentage of their total harvest — premium prices that would not have been possible to realize had lower-quality grains been mixed in.

The second immediate advantage systems like the GRAIN-Q deliver is the ability to make real-time decisions about crop storage. Some of these decisions can be relatively simple. For example, a farmer may choose to dry their grains themselves rather than incur moisture content penalties at a grain elevator. Other decisions, however, can be much more complex, and take into account factors like protein and fat content which can all impact a crop’s susceptibility to mold growth, mircobial activity, oxidation, and rancidity. As such, real-time knowledge of any given grain’s properties can help guide decisions about drying times, temperature controls, aeration and ventilation, etc.

Immediately, these sorts of decisions contribute to multiple incremental value adds to the overall profitability of a farm operation. Having the confidence to safely store grains on site, for example, can allow a farmer to wait for the right moment to sell their crop and fetch the best price. As can the ability to know whether it’s okay to turn down the cooling by a degree or two without impacting crop safety. However, at the more dramatic end of the scale, getting any of these storage decisions wrong can be make-or-break — incorrect storage decisions have the potential to, quite literally, result in the destruction of a crop post-harvest.

The importance of this latter consideration cannot be overstated enough — the UN World Food Program estimates that as much as 40% of grain is lost post-harvest due to inadequate storage. Naturally, this has serious consequences for broad sustainability goals and the global food supply. However, the impacts spread all the way down to the farmer, with many forced into a race to sell grains before decay sets in, which usually results in selling their crop right at the moment while supply is highest and prices are lowest.

Looking Down the Supply Chain

Clearly, the advantages of precision agriculture have already started to spill over beyond the field. But that begs the question: Why shouldn’t similar technologies and techniques be applied to other steps along the supply chain?

This is a question that GRAIN-Q’s developer, TecnoCientifica, first started asking some time ago. One of the results of this was the development of the T-SCANNER — a similar product to the GRAIN-Q, albeit with an entirely different end user in mind — which has since been patented in over 30 countries.

In the T-SCANNER’s case, the end-user in mind was no longer the farmer. Rather, it was grain processing and storage facilities like grain elevators, exporters, and large manufacturers taking in massive quantities of grains — essentially, any facility where the ability to sample grain quality inside inbound trucks and trailers is essential to daily operations.

Traditionally, sampling grains inside trucks and trailers has been done by directly extracting samples at various points in the truck for processing in a lab. Often, this is achieved with a truck probe similar to those produced by companies like Gamet Manufacturing. Essentially, a large hydraulic arm drops a probe into the incoming grain and extracts samples at various points by way of a vacuum system.

Naturally, this can be a relatively time-consuming process. Even with a highly automated on-site lab, the simple fact that physical samples need to be extracted and handled can add significantly to the amount of time needed to process each incoming truckload.

This is precisely where the T-SCANNER shines. In much the same way as precision agriculture technology like the GRAIN-Q allowed farmers to get real-time results the moment their crops were harvested, the T-Scanner allows processing, storage, and export facilities to get similar results in real-time, with no physical sample extraction needed.

The Future of Precision Agriculture

A lot of early precision agriculture innovations tended to focus on large, machine-scale systems like variable-rate applicators (VARs). But, as with any technology, each advance has seen the emergence of increasingly sophisticated and tailored systems.

The consequence of this is that many of the advances we’re seeing are no longer coming from large, instantly recognizable names like the John Deeres of the world. Rather, we’re seeing smaller companies with niche specializations in obscure fields like Near-infrared Spectroscopy — as is the case with TecnoCientifica — coming to the forefront of precision agriculture.

Curiously enough, the flow on effects of this should be largely beneficial to the overall rate of adoption of precision agriculture techniques going forward. For example, previous advances like VARs often necessitated the purchase of entirely new equipment, often with a minimum of a six-figure price tag. Innovations like TecnoCientifica’s GRAIN-Q and T-SCANNER, on the other hand, are often relatively simple retro-fits to existing equipment. This usually means the price of adoption is significantly smaller — often by a factor of 10 — despite the fact the tangible benefits are just as great, if not greater.

This dynamic will also, more than likely, have some broader impacts on the broader agricultural equipment market. After all, if technology like the GRAIN-Q and T-SCANNER not only require niche specialization to develop, but are also designed to be retrofitted to existing equipment, it would seem to make more sense for large OEMs like Gamet Manufacturing and John Deere to increasingly turn to licensing deals to stay relevant. For instance, there is little reason why Gamet couldn’t offer the T-SCANNER as an option across its existing range of truck probes. Presumably, all it would take is a bit of paperwork and a relatively small number of hours spent on systems integration work.

In any case, there is one thing that’s for sure. What may have started as a quiet, under-the-radar movement based on little more than a handful of theories some forty years ago has quickly developed into one of the most important movements since the Green Revolution. For many of us, the 2024 solar storms were the first real wake-up call to just how far precision agriculture has advanced. But, if companies like TecnoCientifica have shown us anything, it’s that tractors guided by GPS down to the nearest inch are just the beginning.

__

(Featured image by no one cares via Unsplash)

DISCLAIMER: This article was written by a third party contributor and does not reflect the opinion of Born2Invest, its management, staff or its associates. Please review our disclaimer for more information.

This article may include forward-looking statements. These forward-looking statements generally are identified by the words “believe,” “project,” “estimate,” “become,” “plan,” “will,” and similar expressions. These forward-looking statements involve known and unknown risks as well as uncertainties, including those discussed in the following cautionary statements and elsewhere in this article and on this site. Although the Company may believe that its expectations are based on reasonable assumptions, the actual results that the Company may achieve may differ materially from any forward-looking statements, which reflect the opinions of the management of the Company only as of the date hereof. Additionally, please make sure to read these important disclosures.

-

Africa1 week ago

Africa1 week agoBLS Secures 500 Million Dirhams to Drive Morocco’s Next-Gen Logistics Expansion

-

Fintech2 weeks ago

Fintech2 weeks agoRipple Targets Banking License to Boost RLUSD Stablecoin Amid U.S. Regulatory Shift

-

Impact Investing3 days ago

Impact Investing3 days agoSustainable Investments Surge in Q2 2025 Amid Green and Tech Rebound

-

Biotech1 week ago

Biotech1 week agoBiotech Booster: €196.4M Fund to Accelerate Dutch Innovation