Business

Here are the 6 best uses for 3D printing in 2017

3D printing has evolved and become valuable to different industries such as retail, construction, food and more.

Depending on how old you are, your recollection of the concept of printing may be entirely different than someone who is ten years older or younger than you.

For the older generation, printing is an exciting concept that changed the way offices and the workforce functioned.

For the younger crowd, its something that’s always been there, much like their view of the Internet.

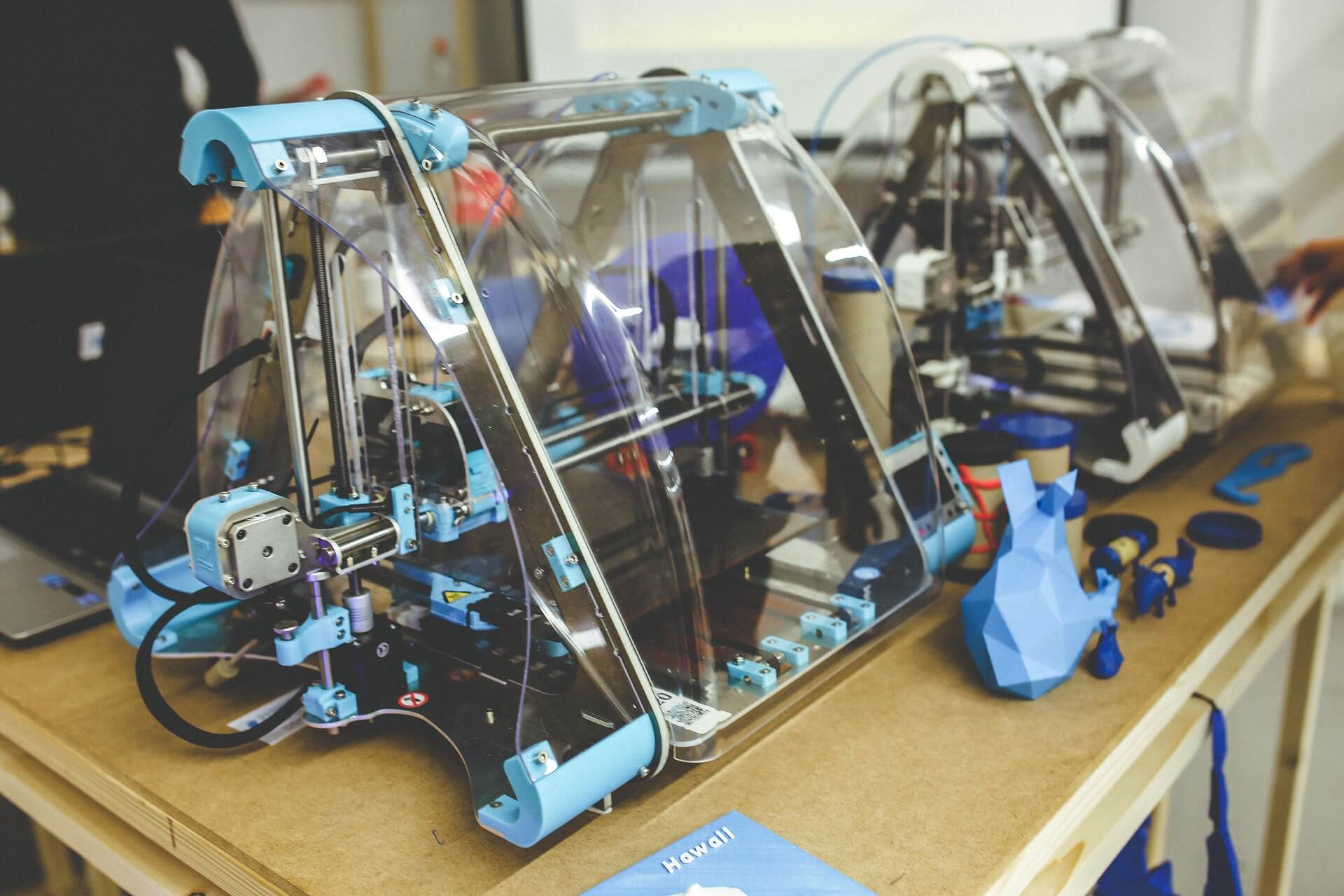

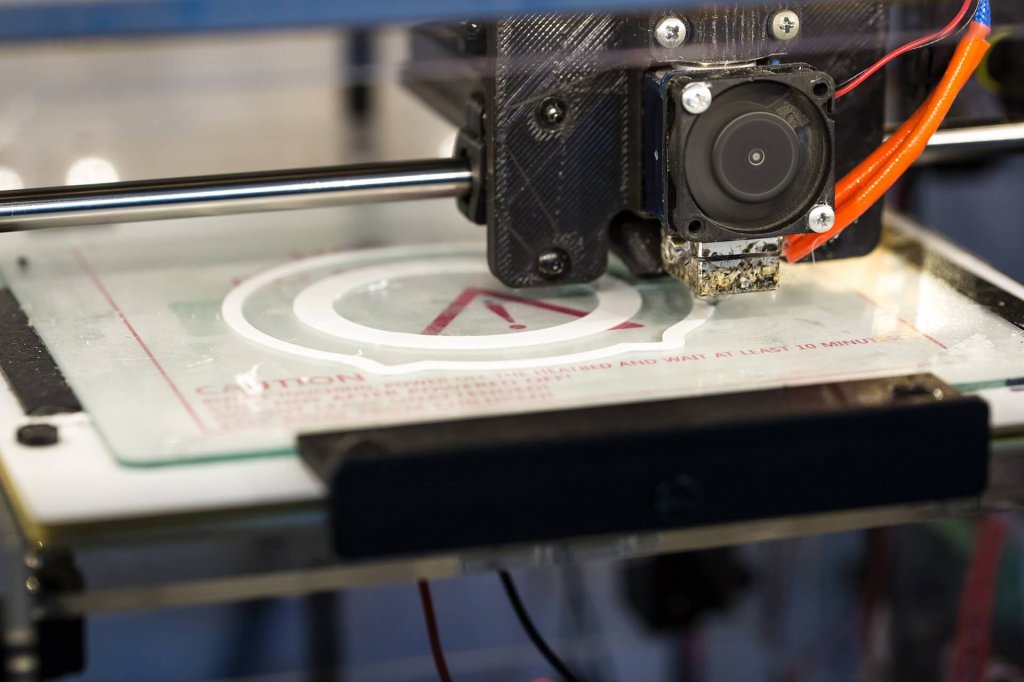

However, society is now entering a new era. 3D printing is the next significant evolution in the printing and technology worlds. Entirely functional objects can now be created quickly from anywhere. It’s a process that will change the future of production.

So, with all this evolution, which way is 3D printing headed? Which ways is the process used?

Listed below are six ways this technology has made an impact in 2017.

1. Construction

It shouldn’t come as a surprise that 3D printing is a boon to the construction industry. When you continuously come up with designs, 3D printing is a massive time-saver. 3D scanners are being used to create scalable diagrams of new buildings, retrofits, and renovations, which can make it easier to spot potential problem areas before construction actually begins.

Blueprints go from the paper on the table to a tangible object that you touch and view from all sides in a matter of mere hours or even minutes. This speeds up both the design and production process, saving builders time and money.

2. Retail

How, exactly, does the retail sector use 3D printing? After all, don’t stores just receive items that get shipped to them from warehouses? While this is true, this new technology enables retail stores to get more involved in the manufacturing process. They can print specialized products in-store and refill their inventory faster.

Retail doesn’t have to use 3D printing on a large scale. Depending on the size of the company, the process can be scaled to produce more or less product.

3. Cars

Even things as intricate as vehicles can be 3D printed. The cars you can buy on the market today most likely aren’t, but with the increased use of 3D printing in almost every facet of technology, it’s only a matter of time before printed cars become common.

2017 has seen the beginning of this process. Auto manufacturers don’t necessarily use 3D printing to produce an entire vehicle at once. Instead, the 3D printer creates individual parts and uses plastic rather than expensive metal. This saves the car manufacturers millions and millions of dollars.

4. Food

Food may be the most surprising entry on this list. How can food be created from seemingly nothing? Printing foods uses the same process as printing other types of products, but instead of using plastic, it uses edible ingredients.

While you can’t yet create every kind of food with this method, companies have created machines that print items that range from chocolates to pizza to burgers.

Medical, technology and many other industries have benefited from 3d printing. (Source)

5. Medical

The medical field is perfectly suited for 3D printing. The process can produce medical instruments quickly and cheaply. It can also enhance scanning procedures. Instead of taking a scan of the brain, for instance, doctors can now create a 3D printed model of it.

Utilizing this aspect of the technology provides many advantages. Doctors can look at the problem from all angles and come up with a solution more easily than they could by studying a 2D scan.

6. Technology

It sounds a little counterintuitive, but 3D printing is picking up the pace of production in the technology field. Some of the more sophisticated 3D printers can make entire laptops. Other printers can create laptop covers and other device accessories.

You can also generate individual parts for devices — a practice that will likely gain more popularity as the years go on. If any component of a machine breaks, you won’t have to order a replacement from the original manufacturer and wait for it to arrive. You can print it and have the part you need almost immediately.

3D printing is here to stay.

As the technology of the future, it’s going to play a central role in how we create and utilize products.

These six industries have already seen how it can improve their processes, and it’s only a matter of time before other areas in society see this same enhancement occur.

—

DISCLAIMER: This article expresses my own ideas and opinions. Any information I have shared are from sources that I believe to be reliable and accurate. I did not receive any financial compensation in writing this post, nor do I own any shares in any company I’ve mentioned. I encourage any reader to do their own diligent research first before making any investment decisions.

-

Business2 weeks ago

Business2 weeks agoLegal Process for Dividing Real Estate Inheritance

-

Fintech12 hours ago

Fintech12 hours agoJPMorgan’s Data Fees Shake Fintech: PayPal Takes a Hit

-

Fintech1 week ago

Fintech1 week agoPUMP ICO Raises Eyebrows: Cash Grab or Meme Coin Meltdown?

-

Africa3 days ago

Africa3 days agoSurging Expenditures Widen Morocco’s Budget Deficit Despite Revenue Growth

You must be logged in to post a comment Login