Business

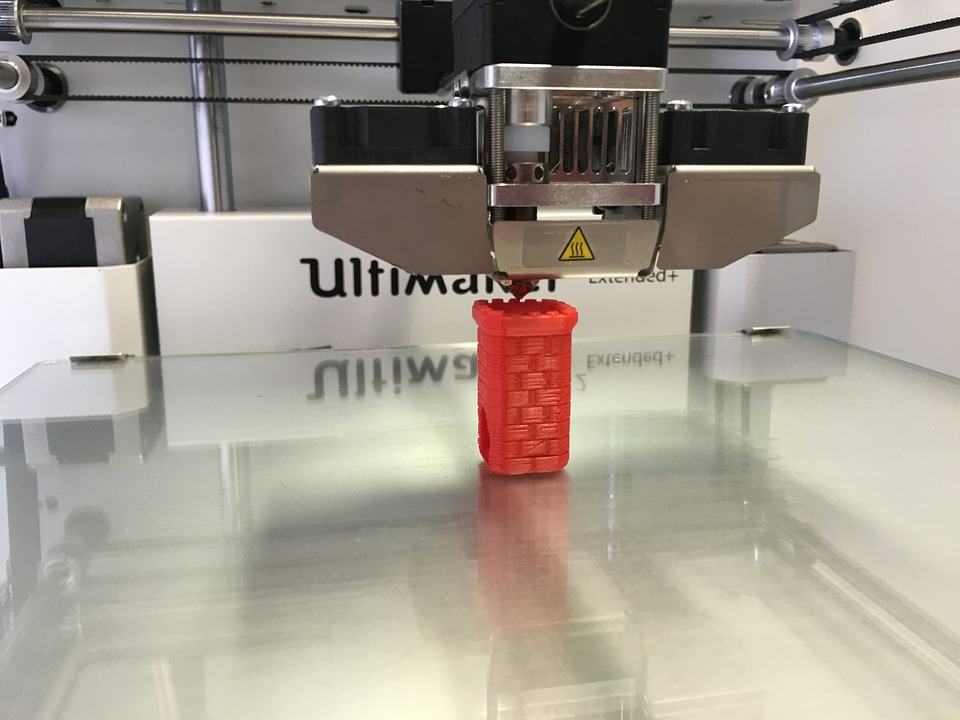

Titanium 3D printing lessens space exploration costs

NASA, Rocket Lab and Spaces X all have explored titanium 3D printing to significantly reduce the average cost of rocket launches.

Mankind is constantly curious about the universe. To understand it, private and public sectors are funding hundreds of millions of dollars to construct and send off satellites and space shuttles. Space exploration has become one of the most vital and expensive forms of research. Titanium 3D printing is one of the latest cost-efficient breakthroughs for space tech.

According to a report by The Guardian, the U.S. federal government has spent over $723 million in NASA funding since 1958 to 2014, with $4.3 million allotted for 2015. These numbers do not include the money spent by private research sectors. Now, 3D printing is the kind of technology that will dramatically lessen these numbers.

NASA’s official website has reported that it has adopted 3D printing in constructing a full-scale copper engine. In particular, this is to reduce the cost and time in manufacturing space additives while maintaining quality. NASA built the copper rocket engine their Marshall Space Flight Center in Huntsville, Alabama. This is for explorers headed to Mars. The product, described as a full-scale copper engine part, is a combustion chamber liner that operates at high temperatures and pressures. Chris Protz, NASA’s Marshall propulsion engineer who led the project, stated that NASA aims to repeat the process in manufacturing other rocket parts to reduce costs.

“We are developing a repeatable process that industry can adopt to manufacture engine parts with advanced designs. The ultimate goal is to make building rocket engines more affordable for everyone,” said Protz.

NASA is also experimenting with Direct Metal Laser Sintering (DMLS). This is a 3D printing method that utilizes space-grade metal materials. Titanium 3D printing is possible with this process, as well as 3D printing with stainless steel, cobalt chrome, and others.

Titanium 3D printing

Private space exploration companies are singing the same tune when it comes to reducing costs. Rocket Lab, a New Zealand-based startup, has used titanium 3D printing to significantly reduce the average cost of rocket launches. The company developed a lightweight satellite launcher called “Electron” along with its engine named “Rutherford Engine” from an additive process using titanium alloys.

3D printing has revolutionized many industries and is now changing the space exploration sector. (Source)

The engine reduced the amount of fuel used. Of course, the also cut down the cost from Lockheed-Martin’s $225 million to $4.9 million. CEO Peter Beck states that the company aims to “commercialize” space access. RocketLab’s first commercial launch that is expected to ready by the end of 2016.

“With Electron, companies can launch whenever they would like, at a substantially more affordable cost. This monumental advancement in space technology gives satellite-reliant businesses the freedom they have been waiting for, which will lead to vast improvements in how we use satellite technology in space,” said Beck in a post by CNET.

Private space system firm Space X also uses fine layers of titanium to create rocket ship part. It does this through an advanced titanium 3D printing machine called “Merlin.” Users need only hand and finger motions to control and create through “Merlin.” The printer that gathers the titanium layers creates the actual engine prototypes. Meanwhile, a laser melts the titanium particles. This also reduces the time and money spent on creating vessels to reach space.

These technologies are made organically possible by a constant supply of the reliable titanium. The space exploration industry now heavily explores titanium 3D printing to plan and carry out these additive processes.

-

Cannabis2 weeks ago

Cannabis2 weeks agoThe Legal Cannabis Industry in the U.S. Provides Over 440,000 Full-Time Jobs

-

Business4 days ago

Business4 days agoBananas Grow in Washington: Powell and FOMC Pinning for Rate Cuts

-

Cannabis1 week ago

Cannabis1 week agoCannabis Legalization Reduces the Likelihood of Youth Using It

-

Cannabis2 days ago

Cannabis2 days agoCannabis Reform in Belgium: What Changes Does the Latest Report Propose