Business

How Elcora’s green tech ensures high-quality graphite and graphene from mining to refining

Elcora Advanced Materials (TSXV:ERA, OTCMKTS:ECORF) has been producing graphite and graphene of the highest quality without negatively affecting the environment.

Innovation has captured the world’s attention. From smartphones to electric cars, we are quickly redefining how we communicate and mobilize in today’s society. Yet, as we welcome advancements brought on by some of the greatest minds of this century, we are also becoming more aware of our ecological footprint. Our concerns now also include further developing a more sustainable way of life through the reduction of waste and an increase in energy efficiency.

Today’s various industries are hard at work in satisfying both technological ambitions and eco-friendly values—finding the balance between the two is crucial. This is perhaps most evident in the mining sector, where modest success can be measured through the purity of a product that is above industry standards, while still complying with rules and regulations designed to protect the environment.

Which begs the question: can a company provide an end-to-end supply chain that guarantees superior quality, from the initial stages of mining to manufacturing, and then onward to large-scale client distribution?

Elcora Advanced Materials (TSXV:ERA, OTCMKTS:ECORF), a Canadian-based graphite producer, believes that it can be done. In fact, at the heart of its operations is the employment of green technology that has been attracting the attention as well as the resources of keen investors looking for the next big thing.

The mineral of tomorrow

To get a deeper appreciation of Elcora’s unique selling proposition, one has to understand first the importance of the product that the company is mining, refining, producing, and distributing to its customers at the other end of the production line.

Like zinc, graphite and graphene are among the minerals that usually fly low under the publicity mill radar. They do not get as much mileage as the more glamorous elements dug from the earth’s core, like gold and silver.

However, they are very much in demand and are vital to the existence and sustainability of the industries that keep our planet alive and well. As the Minerals Education Coalition points out, graphite is critical to the formation and development of steel products. It is essential to the manufacture of brake linings, lubricants, and molds that are used in factories. But more than that, graphite is also regarded as the premiere element that can improve the lifespan of the batteries that millions of users routinely buy to power up their devices such as smartphones, tablets, and laptops.

Graphite is also considered as the “mineral of tomorrow,” as it is a critical component in Lithium-ion (Li-ion) batteries, which are used to power electric cars. Compared to gasoline-based transportation, electric cars are cleaner—and this alone is already changing the landscape.

In fact, an article in Forbes notes that this “electric revolution” can no longer be ignored by traditional automakers. Global response has been so forthcoming that countries like Norway and France are planning to discontinue the sales of fossil-fuel based vehicles by 2025 and beyond.

Bloomberg anticipates that this will increase the mass production of batteries, and the demand for graphite will escalate to 852,000 tons a year come 2030, when it was just 13,000 tons two years ago in 2015.

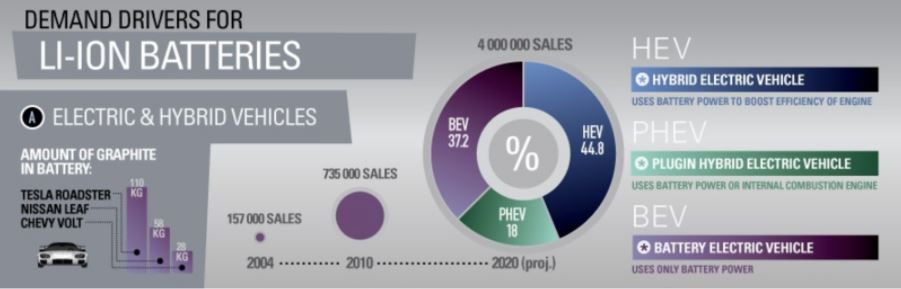

Visual Capitalist also shows that it won’t only be electric cars that will make use of Li-ion batteries; the future will include hybrid vehicles, capturing an even more significant market.

Electric cars will not be the only ones in need of lithium-ion batteries in the future as hybrid vehicles will also require the said batteries. (Source)

Furthermore, Military Technologies recently issued a statement saying that the market for graphite-fueled batteries is increasing, at a compound annual growth rate of 18 percent for the next five years. The purer the carbon element in the graphite, the more juice it can allow the battery to generate, and the more in-demand that particular product will be.

This principle also holds true in every gadget-driven electronically powered consumer industry where batteries are understated, but no less essential lifeline, that makes a consumable product useful and therefore appealing to the consumer. Graphite in batteries speeds up their recharging, eliminating the waste in waiting time that a consumer usually goes through. They also extend the operating time of the device, giving it an edge over competitors. For example, a computer user will naturally gravitate towards a graphite-powered laptop that can run for 12 hours efficiently, as opposed to a non-powered one that can only go for half the time before being plugged again.

The world’s best graphite and graphene

This is where Elcora comes in. Its graphite products are of pristine quality, the purity of its carbon content—to the degree of 97% C—higher than what is found among its competitors. Unlike other graphite produced by newer mining firms, Elcora’s version does not contain or is not contaminated by elements, such as silica, that tend to dilute and depreciate its quality.

No less than the prestigious Center for Advanced 2D Materials (CAD2DM), which is based at the National University of Singapore, has tested Elcora’s graphite products, and certified them as excellent. All categories were ranked above the norm, including but not limited to “percentage of graphene content, average number of layers, and consistency in size.”

One secret to the purity of Elcora’s graphite is that very little chemicals are used to treat it during the actual process of refining and shaping it for the consumer market. Any waste that is incurred as a part of the said process is actually recycled, keeping costs low while preserving and protecting the immediate environment where the production is being done. As reported by Investor Intel, Elcora sources its graphite from its Ragedara site in Sri Lanka, while processing and refinement take place in Northern America. The company also has access to other graphite-producing mines in Africa.

Elcora’s graphite products are of high quality and do not contain elements like silica. (Photo by DerHexer via Wikimedia Commons. CC BY-SA 4.0)

The Sakura mine can produce up to 2,500 tonnes annually, with each tonne commanding a price ranging from $1,500 to $2,500. Production capacity can scale as high as up to 10,000 tonnes a year.

Elcora also maintains its edge over its competitors because it can ensure graphite quality and the environmental sustainability of its production from start to finish. It is involved in all phases of graphite production, from the mining, research, and development, manufacturing, quality control, distribution, to industry compliance.

It monitors every phase of the supply chain, from the time that the graphites are mined from the sites, their transport to the processing plants, the treatment and conversion of the rough material to the final graphite product that the customers are waiting for, and then to another transport procedure where the latter finally get what they had paid for.

Pushing for eco-innovation

Pure and pristine graphite will always be in demand because of the scarcity of its supply. Another driver is increasing market need, fuelled by the constant demands of the current industrial landscape as well as emerging technologies like electric cars and the entire transport chain associated with them.

The kind of graphite that Elcora produces—high quality with very little negative environmental impact—is estimated to capture a market that is worth C$4 billion in by 2020.

Bottomline: protecting the environment while producing high-quality graphite for industrial use does have its rewards. Setting them apart from the competition is a battery and research development lab that continues to explore and innovate the various ways that the full advantages of graphite can be applied to more consumer products. All these should attract investors to Elcora, a major mining company in the making, in droves for the foreseeable future.

(Featured image via DepositPhotos)

—

This article may include forward-looking statements. These forward-looking statements generally are identified by the words “believe,” “project,” “estimate,” “become,” “plan,” “will,” and similar expressions. These forward-looking statements involve known and unknown risks as well as uncertainties, including those discussed in the following cautionary statements and elsewhere in this article and on this site. Although the Company may believe that its expectations are based on reasonable assumptions, the actual results that the Company may achieve may differ materially from any forward-looking statements, which reflect the opinions of the management of the Company only as of the date hereof. Additionally, please make sure to read these important disclosures.

-

Markets1 week ago

Markets1 week agoShockwaves of War: U.S. Strikes Iran, Markets Teeter, Global Risks Rise

-

Crypto5 days ago

Crypto5 days agoCoinbase Surges: Bernstein Targets $510 as COIN Hits Highest Price Since IPO

-

Africa2 weeks ago

Africa2 weeks agoBank of Africa Launches MAD 1 Billion Perpetual Bond to Boost Capital and Drive Growth

-

Markets12 hours ago

Markets12 hours agoCoffee Prices Decline Amid Rising Supply and Mixed Harvest Outlooks

You must be logged in to post a comment Login